Sway

Skills: CAD, machining (mill, lathe), Arduino, electronics, design presentations, project and time management

Sway is a nursing home bed attachment to allow nurses and caregivers to reposition mobility-impaired patients.

- Calculated loads within device to select and source materials.

- Fabricated parts using mill and lathe.

- Met with users to understand design needs and risks.

- Developed within 2 months while working with a team of 14.

- Researched market and developed a licensing business plan.

- Crafted and delivered a presentation to more than 6,000 people.

Yo-yo Design & Manufacturing

Skills: CAD, CAM, CNC milling, injection molding, design presentations

Finished yo-yo molds and some injection molded pieces

Finished yo-yos from manufacturing challenge

- Designed and fabricated column piece of yo-yo.

- Created tool paths for CNC machining (CAM).

- Determined appropriate settings for injection molding process.

- Fine-tuned manufacturing process and molds to eliminate defects and decrease manufacturing time.

- Ensured appropriate tolerance for press-fit part and made adjustments as necessary.

- Worked in a group with 4 other students.

Robot Design Project

Skills: CAD, machining (mill, lathe) and CNC, waterjet, Arduino, power tools (drill press, bandsaw, disk sander, hand drill), design presentation, project and time management

Side view of robot, showing the hook and 4-stage lift in starting position.

Robot in fully extended position, reaching height of 41 inches and able to lift around 30N.

Bottom of robot, showing the 4-wheel drive configuration and the lower winch.

- Individual project to design and manufacture robot to compete in a game challenge in 3 months.

- Placed in top 16 robots out of more than 110.

- Designed 4-stage lift that can raise 30 N, extend to 41 N, and pull down 17 N.

- Developed a hook mechanism to grab onto a game piece and a dive base with 4 wheel drive.

- Calculated necessary motor specs, weight, center of mass.

- Manufactured almost all parts of robot, using mill, lathe, waterjet and other power tools.

- Programmed autonomous period using Arduino.

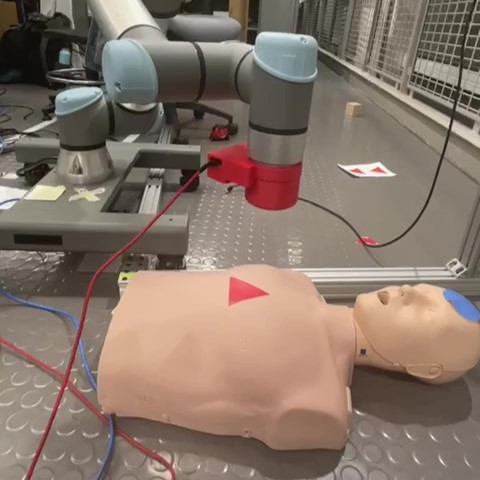

CPR Robot

Skills: Programming, computer vision, feedback control systems

The purpose of this project was to use a UR5 6 DOF robot to perform CPR on a mannequin.

- Developed code to recognize target location on the mannequin's chest.

- Used force sensor data to implement force control while applying a cylic pattern of force to the target point on the mannequin, replicating CPR.

Toy Design Project

Skills: developing prototypes, prototyping techniques (foam core, woodworking, blue foam), oral presentation, design process, working in diverse teams

Original game concept for initial presentation.

Blue foam and foam core model of the game during development.

Final prototype of game with electronics and game pieces.

- Developed a working, professional prototype of a toy in a semester in a group of 5. The toy is called Twisted Toss,

similar to cornhole but the board twists and lights up as the game is played.

- Selected materials, decided appropriate motor, and assembled final product.

- Set goals and timelines for the group, developed script for final presentation

- Play-tested with children at a local children's museum.

- Experienced design process from brainstorming, sketching, sketch modeling, prototyping, and presenting the final product.

Below you can find our "playsentation", our presentation presented as a play.

Controls Projects

Skills: designing PD and PID controllers, implementing lead and lag compensators, programming Arduino, MATLAB Control System Designer (SISOTOOL)

As a part of my Dynamics and Controls II class, I designed lead and lag compensators, as well as PD and PID controllers. For one lab, my lab partner and I designed a PD and PID controller using MATLAB's SISO tool for a segway-like robot. After programming the controller into Arduino, the robot was able to stay upright in a 1 ft. x 1 ft. box for over an hour!